If you want to understand how a sewing machine works, this video is really good.

If you want to understand how a sewing machine works, this video is really good.

I like scrappy quilts, especially the ones with small pieces and many different prints. But getting organised so that you have a good mixture of prints, well spread out, and still maintain a pattern puts me off.

So when I heard about the idea of using a printed paper to simplify the process, I thought I’d give it a go.

You take two layer cake squares (10″), put them right sides together, add a “cake recipe” paper on the top, and then sew round ne set of lines, and cut on the other. That gave 16 small half square triangles and 1 large half square triangle, with a bit left over, in case you want any plain squares. Or in case you are like me and manage to lose one of the small squares.

I’m very pleased with the result, but sewing the papers and cutting them apart was a very dull task. Normally while you are doing patchwork, there is the pleasure of looking at all the fabrics. I was just looking at the grey paper all that time. But you can’t have everything, and it is certainly an easy way of keeping everything accurate, and keeping track of the numbers.

I used 3 layer cakes, made 42 blocks, and joined the rest together to make the backing. The backing was large enough for me to turn the edge over and use as a binding. The border is a little wobbly, but it is from the automatic patterns on my sewing machine, so I can’t use the walking foot, so it is difficult to control.

For many years, I’ve been thinking about doing a block of the month project. There are usually a good selection available, but I never took the plunge. Sometimes there was a nagging idea that I could work something similar out for myself, and I would like it more. Usually I know that, although I really like the result, I won’t enjoy the technique.

Then in 2020, I started two block of the month projects.

This map of the UK has far too much applique in it for me, but I decided that the result would be worth it, and I went for it. To start off with, I kept up with it reasonably well, but then I got to the point where the next job was to embroider all the counmty names. I hadn’t decided what landmarks I wanted to include, so I was worried that I might find I’d written somewhere I wanted a picture.

The map was divided into regions, so the counties could be assembled in manageable units. That worked fine, and I made good progress. The problem came when I put the when country together. Somehow, there is a problem in the middle, so Yorkshire and Lincolnshire overlapped, and the Humber didn’t exist. Eventually, I managed to fix that, and the county boundaries are slightly wider here and there to cover the gaps.

I’m quite pleased with the way it has turned out:

You know how one thing leads to another?

Our first “outside speaker” at the East Yorkshire Embroidery Society when we ventured onto zoom was Elizabeth Almond, who talked to us about blackwork. I told her that years ago, I made a sampler of the UK, by tracing a map of suitable size from my school atlas, and sellotaping a piece of graph paper behind it to make a chart. She said “I do encourage you to have another go. There is such a lot you can do.”

Yes, right. Along with all the other textile things I’m going to do when I have a moment…

But then I saw a picture of a clock on Pinterest. It was quite nice, but I was sure with a bit of thought I could do something I liked more. Cue more “research” time, looking at books and Pinterest, mostly adding to the list of what I’m going to do when I have time rather than refining my clock design. Blackwork chess boards came up a lot, which is no surprise. A chessboard gives lots of nice even shapes ready to be filled in, so they are a good excuse for blackwork.

I was going to make a chess board years ago. My ex was a keen chess player (North Yorkshire Police champion for many years, no less), and he thought it was a brilliant idea. But we couldn’t work out where to put it, as the only sensible place for it was occupied by his beautiful wooden board. So I played other games instead.

Then it occurred to me that there is no reason why I couldn’t get back to that idea. Then my eye was caught by the Lewis queen who sits next to my screen. So I spent my Christmas present money on a Lewis chess set, and made a board to fit them.

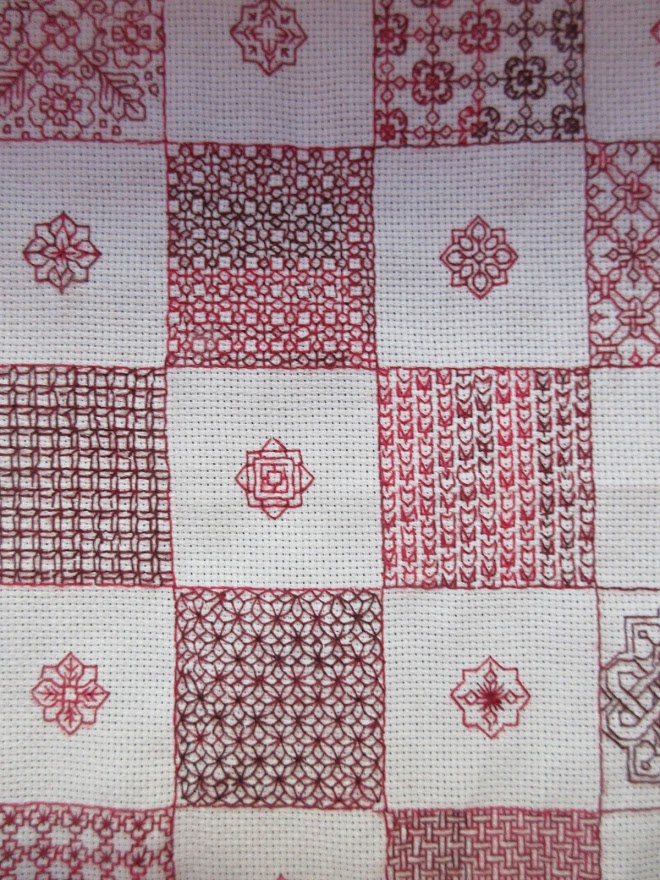

Here is the result:

I’m now working on a blackwork solitaire board to go on the other side. I’m, planning to play on that using the pawns.

Many years ago, I needed to make myself a costume involving a bustle. I had plenty of pictures of the real thing, but couldn’t find any clues about how to start the construction. This book from 1888 was just what I needed. It has all the patterns you need to recreate an entire wardrobe.

Not that I need things like that any more. But it doesn’t stop me from having a good look!

This is an interesting post about clothes lines in New York.

This little woolly animation about the history of spinning is well worth the couple of minutes it take to watch.

My first post of 2021 is to pass on an interesting article about the history of dyes.

There are some fabulous pictures in this post.

As usual, my favourites are the sample cards showing the range of colours.

But as you would expect from the Science Museum, there are also lots of interesting facts to read.

Every now and then, when it happens to catch my eye, I pick up a copy of Quilting magazine when I go to Tesco. Not long before the first lockdown, I got a copy with a couple of rainbow coloured designs on it. Inside, I found a fabulous design for a Somerset folded patchwork cushion.

Every now and then, when it happens to catch my eye, I pick up a copy of Quilting magazine when I go to Tesco. Not long before the first lockdown, I got a copy with a couple of rainbow coloured designs on it. Inside, I found a fabulous design for a Somerset folded patchwork cushion.

Now I’m never very good at Origami. It requires a certain level of precision that I can’t maintain for very long. My attention tends to wander, and mistakes creep in. But this one had to be worth the effort.

The only other time I have attempted anything like this was in 1/12 scale, using tiddly bits of 1/4 inch wide ribbon. Every time I tried to sew anything down on that project, something moved ever so slightly and messed everything up. Once bitten, twice shy.

The only other time I have attempted anything like this was in 1/12 scale, using tiddly bits of 1/4 inch wide ribbon. Every time I tried to sew anything down on that project, something moved ever so slightly and messed everything up. Once bitten, twice shy.

So it took me a long time to get round to it. I knew that once I started sorting my stash, I would get to a certain stage where there was mess everywhere. Inevitably, I wasn’t going to have all the colours I needed in my stash, and this isn’t the year for keeping an eye open for extras when out and about.

But a few weeks ago, I made a list of what I needed, and started the hunt for candidates. I needed 4 squares in various sizes of each of 8 colours. Well, there are four courners, and you need to join them along the sides with 4 more. To make that work with seven colours of the rainbow, indigo has been dropped, and turquoise and pink have been added.

As it turned out, I had almost all I needed. I needed a turquoise and a yellow, but as I didn’t need a specific match that was easy enough to rectify online.

Some of my squares are rectangles, but by using a bit of paper I worked out that as long as I had the correct measurement one way and more than half the measurement the other, it would work. The idea is to fold the square in half, then fold the top corners to the bottom edge to form a flying goose style triangle, and then layer them up to make the pattern. That means if one measurement is correct, and the other is long enough to hide the raw edge, you are in business.

Some of my squares are rectangles, but by using a bit of paper I worked out that as long as I had the correct measurement one way and more than half the measurement the other, it would work. The idea is to fold the square in half, then fold the top corners to the bottom edge to form a flying goose style triangle, and then layer them up to make the pattern. That means if one measurement is correct, and the other is long enough to hide the raw edge, you are in business.

Mostly, I’m very pleased with the way this turned out. I had a little trouble with the last two rounds of triangles. I have a feeling that the geometry wasn’t quite right, and it would have been better to cut the fabric a little larger. But it could easily be me not being accurate enough. It doesn’t matter, because I can live with the result. I have to look quite hard to see the problem.

I was particularly pleased with the way this random selection of fabrics worked together. I thought while I had them all out, I might do another of the designs. But the only one that would work with a cushion I’d got was 25 different half square triangles. I’m not keen on sewing bias cut edges together, so I like the various methods of making multiple half square triangle blocks at once. That would mean both sides of the cover being the same, which I wasn’t sure I wanted.

I was particularly pleased with the way this random selection of fabrics worked together. I thought while I had them all out, I might do another of the designs. But the only one that would work with a cushion I’d got was 25 different half square triangles. I’m not keen on sewing bias cut edges together, so I like the various methods of making multiple half square triangle blocks at once. That would mean both sides of the cover being the same, which I wasn’t sure I wanted.

I’ve been looking at the hunters’star block for a while, and I thought I’d see if I could make it work for this. There are all sorts of methods for doing this block, including using a special ruler, and another that involves long bias cuts. Then I found this post about combining half square triangles and squares. I cut 3 coloured 3.5 inch squares and 3 white squares for each block, and ended up with a square of about 18 inches. The half square triangles were made four at a time, sewing all round the squares, and then cutting across both diagonals.

So what else can I do with these fabrics? I’ve been meaning to try wonky log cabin for a long time, so I did a block of that, and quilted it in a spiral.

So what else can I do with these fabrics? I’ve been meaning to try wonky log cabin for a long time, so I did a block of that, and quilted it in a spiral.

I decided this one shouldn’t have a plain back , so I’ve sewn together some 2 1/2 inch strips, quilted with random lines. I think the two sides of this cushion work well together.

, so I’ve sewn together some 2 1/2 inch strips, quilted with random lines. I think the two sides of this cushion work well together.

I briefly considered making another using a house block. I’ve seen one on Pinterest that just uses red and white fabrics, in 4 blocks.

I can’t quite get my head round translating this idea into many colours.

So for now, I’m quitting while I’m ahead. I’m now running out of boring cushions that came with the sofa!

Now, here is an idea for a trip when we get back to normal.

Now, here is an idea for a trip when we get back to normal.

Perhaps next summer, or the one after that.

Roubaix was famous for its textiles from 18th century onwards. These days it is a suburb of Lille, which must make it possible via Eurostar.

I’ve been on Eurostar a few times, and driven through Lille as well, and thought it looked an interesting place. May be that is what I shgould do with my stash of euros.

Read more about Roubaix here.